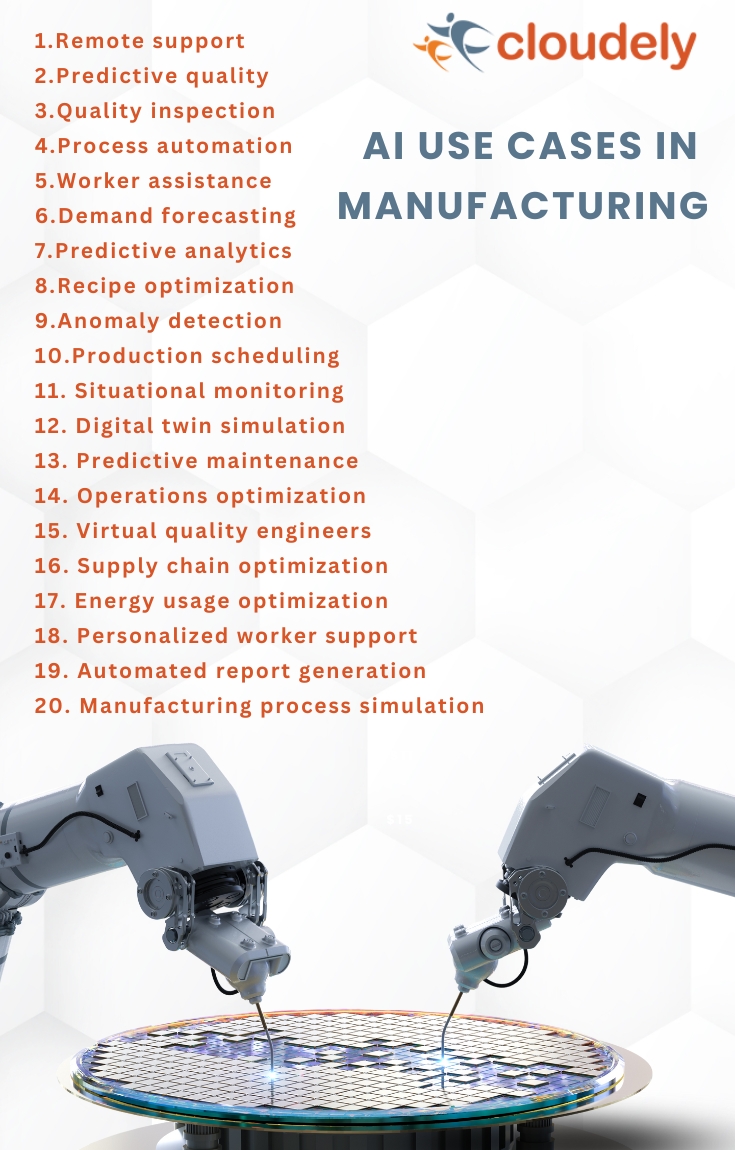

Artificial intelligence is transforming industries at a rapid pace. Manufacturing has quickly adopted cutting-edge AI technologies to optimize operations and gain a competitive edge. But which AI use cases make a difference on the factory floor? This article explores 20 insightful ways manufacturers apply AI to boost quality, efficiency, and profitability. Prepare to be intrigued by the disruption and opportunities ahead.

AI in Manufacturing Use Cases

Below are the powerful and practical AI use cases being adopted across the manufacturing sector.

Demand forecasting

Accurate demand forecasting allows manufacturers to align supply with demand, reducing inventory costs and lost sales. AI uses past sales data, market trends and external factors like weather or holidays to forecast demand accurately. For example, consumer packaged goods companies use AI to analyze SKU-level sales patterns and predict demand at the store level weeks or months in advance.

Predictive maintenance

AI can analyze machine sensor data in real-time to predict maintenance needs like repairs or parts replacement before breakdowns occur. This maximizes uptime while reducing maintenance costs. For instance, an industrial equipment maker trains neural networks on 50 parameters from each machine to determine the likelihood of failure within the next month.

Supply chain optimization

AI sheds light on upstream and downstream inefficiencies across the extended supply chain. It considers millions of variables to detect issues and recommends reducing bottlenecks and lowering transportation and inventory costs.

Operations optimization

AI finds hidden optimization opportunities on the plant floor by assessing equipment usage patterns, labor allocation, energy consumption trends, and maintenance schedules. For example, a factory schedules energy-intensive jobs when electricity prices dip to save $250k annually on utility bills.

Quality inspection

AI improves quality by automating visual inspection of products on assembly lines using computer vision. Neural networks trained on defect images catch imperfections that human eyes may miss. An automaker prevents flawed car doors from shipping by using AI to detect flaws with 98% accuracy versus 75% for human inspectors.

Process automation

By studying videos of workflows, AI helps automate repetitive manual tasks to boost productivity. It generates step-by-step instructions for robotic arms to perform jobs like labeling, order picking, or assembly autonomously. This allows the redeployment of workers to more engaging roles.

Predictive quality

AI models analyze metrics throughout production to predict the likelihood of defects. This enables proactive corrections before non-conforming products are made. For example, an analysis of 35 sensors from an injection molding machine alerted operators to adjust temperature settings, avoiding a flawed product run.

Production scheduling

AI optimizes scheduling orders, machines, materials, and workers based on constraints like deadlines and available capacity. Its goal is to complete jobs quickly while keeping utilization and changeovers low. Using an AI scheduler, a computer maker reduced average production time by 12%.

Suggested Reading: How does Salesforce Manufacturing Cloud help companies?

Virtual quality engineers

By training on root cause failure analyses, AI can serve as an automated “quality engineer.” It detects quality issues in real-time, pinpoints root causes that may be difficult for people to spot, and prescribes remedies. This enables continuous improvement at a lower cost compared to hiring expert engineers.

Situational awareness

AI surveillance cameras monitor factories for worker safety, asset protection and operational insights. Advanced vision algorithms alert managers to hazards, policy violations, process deviations or other issues on the plant floor in real time. This facilitates faster problem resolution.

Manufacturing process simulation

AI helps virtually simulate complex manufacturing processes before production to detect design and engineering flaws. It identifies ways to improve quality, yield, and throughput and eliminate recalled products down the line, avoiding costly physical trial-and-error experimentation.

Worker assistance

AI enables new forms of workflow guidance by generating step-by-step task lists, checklists and work instructions for employees on mobile devices or smart glasses. Computer vision recognizes tools or tasks and then provides guidance. This boosts productivity by preventing errors and rework.

Predictive analytics

AI extracts patterns from production data to forecast outcomes like equipment failure rates, demand volatility or product yields up to 6 months in advance. It alerts decision-makers to emerging trends and issues so they can proactively adjust parameters, orders or budgets accordingly.

Energy usage optimization

AI uncovers ways to use energy more efficiently on the plant floor. It tracks consumption patterns over time and recommends shifting energy-intensive jobs to off-peak hours or automating manual tasks requiring excess energy. This lowers utility expenses.

Digital twin simulation

AI powers virtual replicas or “digital twins” of products, factories, and production lines. It runs optimization simulations on digital twins to find ways to boost quality, maximize throughput, and minimize waste without business disruptions – before applying changes in the real world.

Automated report generation

AI enables access to insights buried in production data by automatically generating customized reports on key performance indicators. It identifies trends, outliers, and problem areas to highlight for supervisors, eliminating time spent on manual data crunching and report writing.

Recipe optimization

AI optimizes recipes by determining the best formulations, settings, and manufacturing parameters to produce parts with ideal quality characteristics. It reduces manufacturing formulation and calibration experimentation time from months to days, minimizing wasted materials.

Anomaly detection

AI monitors production equipment in real-time, analyzing sensor readings against historical baselines. It alerts operators immediately to any anomalous deviations that could signal quality issues, downtime risks, or safety hazards before they snowball into more significant problems.

Personalized worker support

By identifying behaviors from videos of best practices, AI helps less experienced workers improve their skills. For example, smart glasses with AI use augmented reality to visually overlay optimization steps directly in the user’s field of vision as they perform manual tasks.

Remote support

AI helps with geographically dispersed maintenance. Computer vision-enabled smart glasses let experts visually see machinery from remote locations. They can guide on-site staff through repairs by overlaying annotations directly onto live video feeds of the production equipment.

Suggested Reading: Retail and Manufacturing Technology Challenges

AI’s Impacts are Only Beginning

While the journey with any emerging technology involves a learning curve, manufacturers prioritizing strategic AI adoption will gain a sustainable competitive edge in today’s digital economy. The future of manufacturing depends on how healthy companies embrace this robust set of tools to drive innovation.

Cloudely is a fast-growing Technology Implementation and Staffing Partner for leading organizations. Connect with us at hello@cloudely.com to take your business growth to the next level.